Dicing before Grinding (DBG)

DBG is the preferred process when both dicing and grinding has to be performed on thin wafers. DBG is the application to achieve demands for ultra-compact packaging, handling large diameter wafers and guaranteeing a higher yield due to zero wafer breakage. The wafer is initially grooved using a process called Half Cut Dicing. Subsequently, back grinding is performed until reaching the groove and, thus, separating the dies. Dicing before grinding is the convenient complete package offered by KKM Services ensuring a perfect backside quality and zero edge chipping.

Surface Planarization

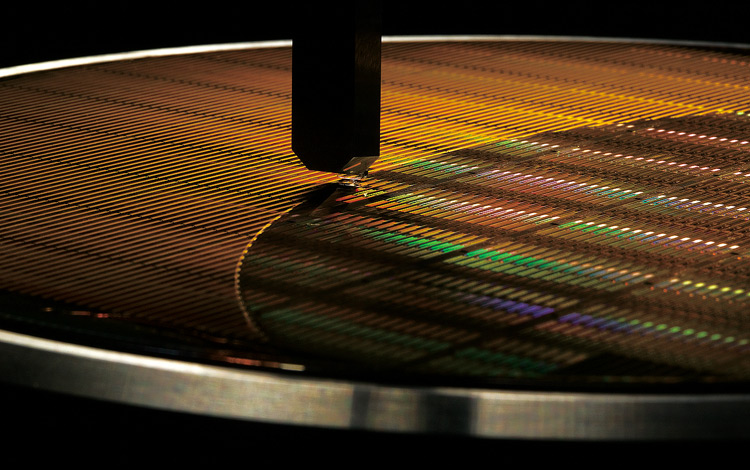

KKM Services provides high-precision planarization of ductile materials such as gold, copper, solder, polyimide, or resins and compound substrate by processing with a diamond bit. Likewise, surface planarization is a solution for reducing bump height variation and surface unevenness. It can also be applied for tape planarization prior to grinding to reduce total wafer thickness variation (TTV).

Other applications are possible, e.g. handle wafer removal from SOI wafers.

Send us your service request now