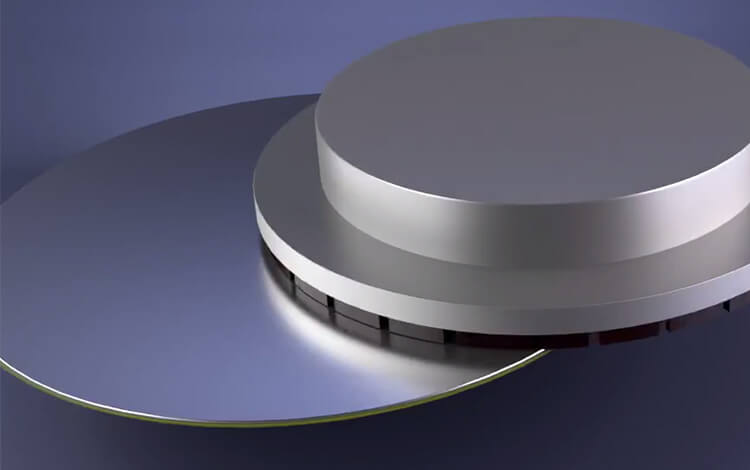

Wafer Backgrind

DISCO’s fixed abrasive, dual step grinding process is able to achieve excellent thickness tolerances and the fine grind wheel can control surface roughness to a nanometer scale. Advanced wafer handling methods allow us to thin wafers to below 100um final thickness, in some cases much thinner than 100um.

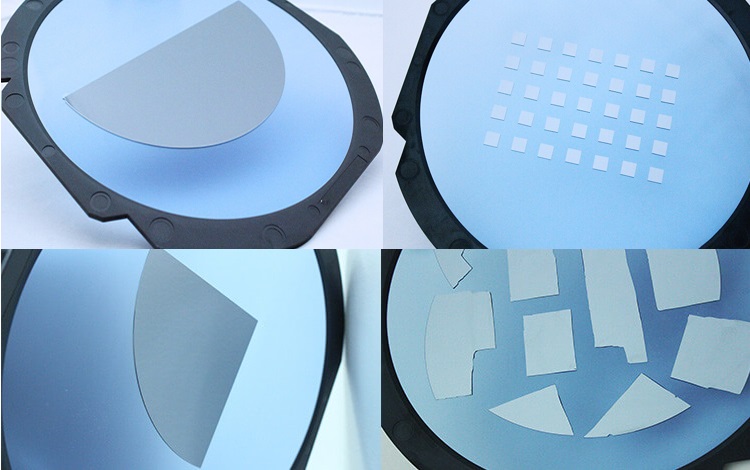

Chip and Partial Wafer Grinding

Individual die as well as partial or broken wafers can be mounted to a frame and ground to target thicknesses so that they can still be diced and packaged.

Poligrind

Poligrind wheels with super fine diamonds deliver high wafer strength and excellent backside surface finish. This technology means that post grind stress relief is not necessary, lowering costs significantly while also reducing the environmental impact.

Send us your service request now