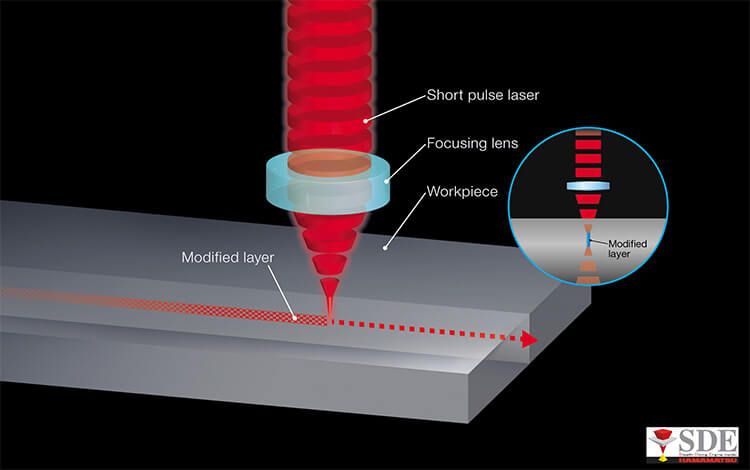

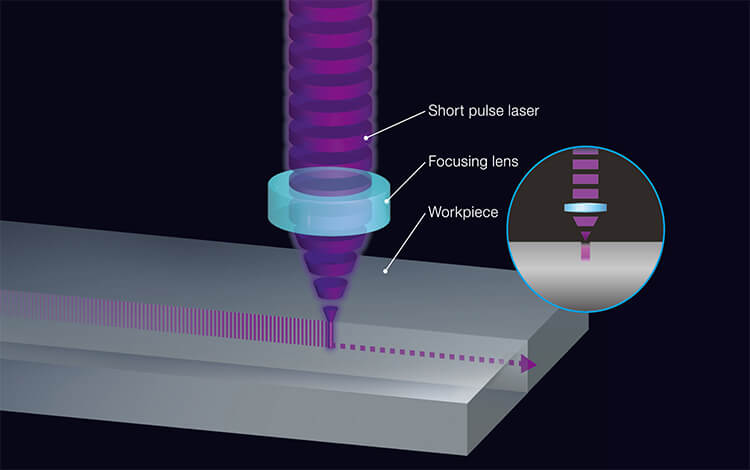

Stealth Laser Dicing (SD)

Stealth dicing is a zero-waste, dry process which does not require any cleaning. Kerf width can be drasticly reduced. Stealth Laser can be applied to multi-project-wafers (MPW) or MEMS and various materials, as the dry process suits products which have to be protected from water or contamination. SD is a two-stage process. Firstly, the laser beam is focused in the inside of the workpiece creating a so-called modified layer/SD layer. Secondly, in order to separate the dies, external force is applied to singulate the dies along the modified layer.

Stealth Dicing of Different Materials

SiC is a promising material for power devices due to its capability, breakdown voltage, high strength, cooling ability and reduction of power loss. However, due to its hardness, it is difficult to process. Chipping may occur using blade dicing on SiC. In some cases, metallic layer on the back side is prone to burring. Reducing blade rpm (rotation per minute) and cutting feed speed can help, but reduces productivity. Our solution: Stealth Dicing on SiC maintains high productivity and highest quality eliminating any burrs.

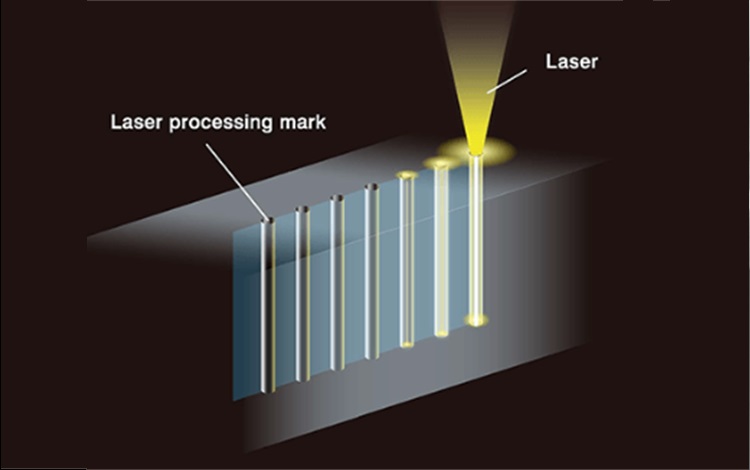

Laser Ablation

Laser Ablation is implemented by focusing laser energy onto a minute area for a very short time. Thus, solid evaporates and sublimes. There are various types of laser ablation depending on material being processed and also type of processing application, such as laser grooving and scribing.

Laser Grooving

Laser grooving technique offers benefits particularly when dicing low-k-materials. First, the material, which is difficult to be processed by dicing blade, is removed by laser grooving. Laser grooving is followed by step cut or single cut by blade dicing. Chipping or delamination of the low-k layers is reduced to a minimum.

LEAF (Laser Enhanced Ablation Filling)*

Ultra-fine process of Quartz, Glass, and Crystal Using Free-Shape Laser Processing.

*Also capable of dicing thicker substrates.

Send us your service request now